What is ‘the Vibration Test’?

The Vibration Durability Test is used to ensure that newly designed products can survive in use during their lifespan

and operate satisfactorily against any vibration stress, thus inevitably required to win over the tough market.

Purposes of

Vibration Tests

-

Vibration Durability Tests

For Parts for Automobiles, Electronic Devices, Airplanes etc.

To ensure that newly designed products can survive in use during their lifespan and operate satisfactorily against any vibration stress

-

Transportation Tests

For Home Electric Appliances, OA Apparatus etc.

To ensure that products, to be shipped, can survive during transportation against any vibration stress, including their package

-

Stress Screening in Production Line

At Various Hardware Assembly Levels

To check on parts/workmanship failures at module, unit and system levels; the lower the assembly level, the fewer total failure

-

Anti-earthquake Measures

For Construction, Gas Heater, Oil Stoves etc.

Research to prevent or minimize damage/destruction/

performance trouble on constructions, equipment etc. by earthquakes -

Calibration of Vibration Meters and Seismometers

Calibration & Performance Check of Vibration Meters, Seismometers etc.

-

Vibration Analysis and Measurement

For Vehicles, Vessels, Trains, Construction, Metal etc.

Fundamental tests for designing by measurements of vibration response on parts, material, structure etc. and mechanical impedance

-

Production Process Assistance

Fling up Churning of Industrial Powders & Fluids etc.

Vibration Test Standards

Main international vibration test standards are as follows:

SHINKEN manufacture Vibration Test Systems which can meet various vibration test standards.

Search Based Upon Usage and Industries

| Standard Number | Contents |

|---|---|

| IEC 60068-1 (=JIS C 60068-2-6) | Environmental testing -- Part 2-6: Tests – Test Fc: Vibration (sinusoidal) |

| IEC 61960 (=JIS C 8713) | Secondary cells and batteries containing alkaline or other non-acid electrolytes -- Mechanical tests for sealed portable secondary cells and batteries |

| JIS D 1601 | Vibration testing methods for automobile parts |

| ISO/IEC-16750-3 (=JASO D 014-3) | Road vehicles — Environmental conditions and testing for electrical and electronic equipment |

| ISO8318:2000,13355:2016 (= JIS Z 0232) | Packaged freights -- Method of vibration test |

| ISTA | International Safe Transit Association: Performance Tests for Packaged-Products |

| ASTM D4169 | American Society for Testing and Materials Standards: Standard Practice for Performance Testing of Shipping Containers and Systems |

| IEC61373 (=JIS E 4031) | Rolling stock equipment -- Vibration and shock tests |

| IEC 60529 (=JIS F 8006) | General requirements for vibration test of electrical apparatus for marine use |

| ISO 2685 (=JIS W 0812) | Airborne equipment -- Environmental conditions and test Procedures |

| JIS S 1018 | Test methods of vibration and earthquake tumbling for furniture |

| UN38.3 | United Nations Lithium Battery Testing Requirements |

| JEDEC Standard JESD22-B103-B | Vibration, Variable Frequency |

| NEBS(Network Equipment Building System) GR-63-CORE | Seismic qualified enclosures for telecommunications equipment and components |

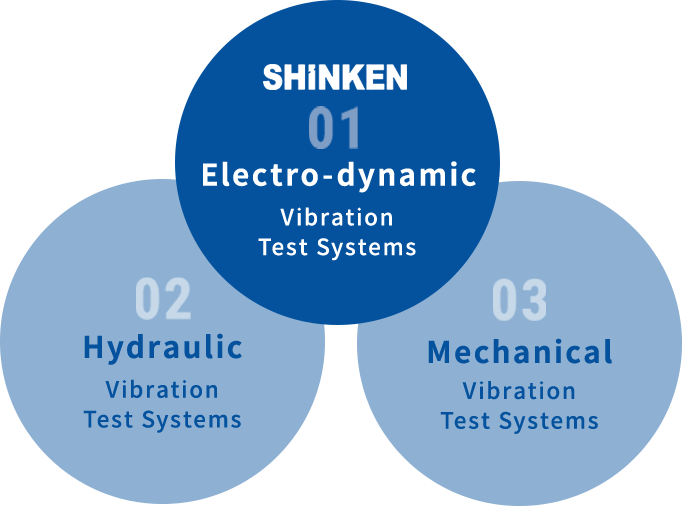

Types of Vibration

Test Systems

Vibration test Systems are categorized into 3 Types with vibration generation methods

The Mechanical Vibration Test Systems, cheap (about 1/10 of Electro-dynamic System’s price) but usable only for simple ‘far-from-real-world-vibration’ sine tests, have almost become extinct as ‘more-realistic-real-world-vibration’ random tests have become more and more popular.

The Hydraulic Vibration Test Systems, featured by large force, are said to be a little bit cheaper than the Electro-dynamic Vibration Test Systems as far as larger systems than 50kN with large vibration tables are concerned, while the running cost including the maintenance cost for the Hydraulic Systems is far higher with a lot of oil being used.

Also the hydraulic power supply system used for the Hydraulic Systems caused a very annoying noise problem, which is against the world trend putting more importance to ‘Environment’ at present. In addition, the usable upper frequency of the Hydraulic Systems is said to be much lower than that of the Electro-dynamic Systems at about 200Hz as well as to be less controllable due to slow oil response against input control signals.

At present there exists almost no competition between the Mechanical Vibration Test Systems and Electro-dynamic Vibration Test Systems while there exists competition between the Hydraulic Vibration Test Systems and Electro-dynamic Vibration Test Systems as far as large systems over 50kN are concerned.

The Principle of

Electro-dynamic

Vibration Generators

SHINKEN's Vibration Test Systems are of an Electro-dynamic type. The principle and features of the Electro-dynamic Vibration Generators are as follows:

-

‘Fleming's Left-hand Rule’, the electromagnetic effect that ‘when an electric current is applied to a conductor in a magnetic field, the conductor receives a force’ is widely applied to various devices such as motors, speakers and meter instruments including Electro-dynamic Vibration Generators.

Its principle is as follows:

There is a gap in the cylindrical magnetic path as shown in the right drawing and the driving coil being supported with the spring is inserted in the gap. When a direct current is supplied to the field coil in the magnetic path, the magnetic flux is generated in the direction of the arrows shown in the drawing and the DC magnetic field is produced in the gap. Then by applying an alternating current to the driving coil, the driving coil is being moved up and down, which is called ‘Vibration’.

The generated force is proportional to the alternating current level to be applied. -

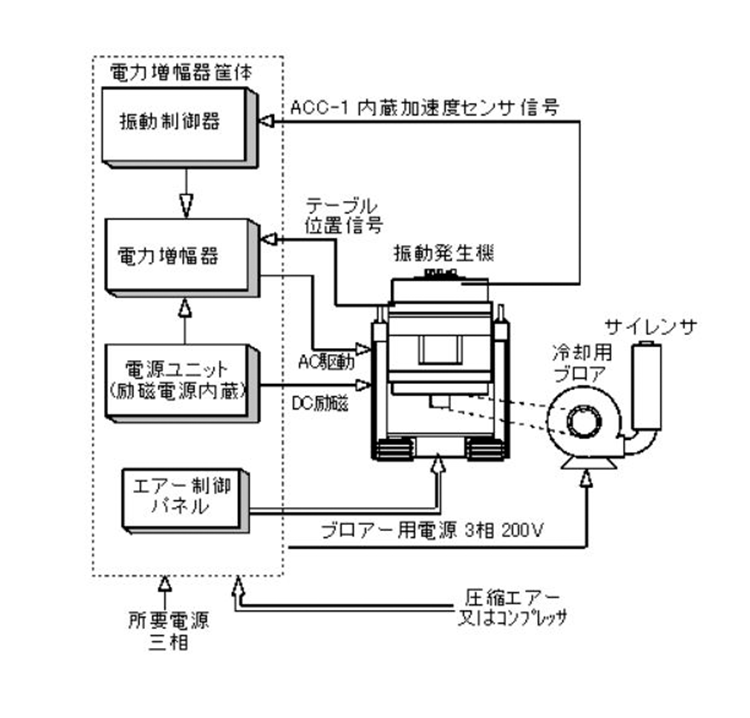

The structure of the actual Electro-dynamic Vibration Generators is very complicated with a variety of specially-designed parts and components being built in to improve the magnetic flux efficiency of the above-mentioned field coil(s) and also to maintain stable long-time operation with the Electro-dynamic Vibration Generators featured by the wide frequency range and high acceleration being capable of easily generating the required amount of vibration in the designated time-domain waveform or frequency-domain pattern simply controlling the current. The typical Block Diagram of the Electro-dynamic Vibration Test System is shown on the left side. This is the basic configuration and other devices are to be added depending upon the test conditions and usage.

Solution to Vibration with SHINKEN

Transport Access

SHINKEN is located about 1 km away from Chuo Expressway Hachioji Interchange.

For those coming

by train, take a taxi from JR or Keio Line Hachioji Station (About 15 minutes by taxi).

- Chuo Expressway

- About 1km from Hachioji Interchange

- From JR or Keio Line Hachioji Station

- About 15 minutes by taxi