-

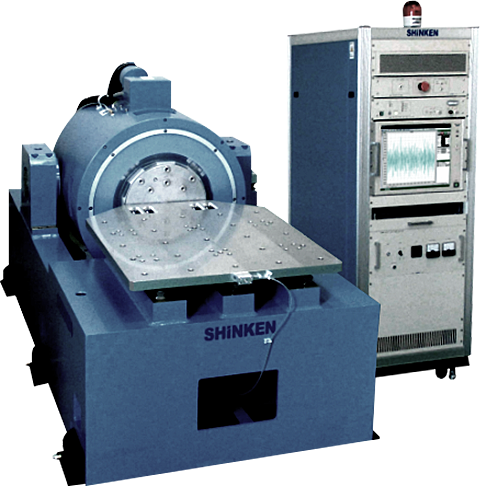

Single-axis Vibration Test Systems

A Variety of Choices

The Single-axis Vibration Test Systems, the most common, have been widely used for many years. Even for Conventional Single-axis Vibration Test Systems, SHINKEN has been meeting various customer's requirements with unique technologies such as Air Bearing and Hydrostatic Bearing for guiding the Movable Mass and Bellows-free Air Suspension for Axial Support using Back Pressure from the Air Bearing System; N Type: Air Bearing & Air Suspension* featured by High Fidelity, Low Cross-talks, Cleanness and Fewer Consumable Parts L Type: Hydrostatic Bearing featured by High Eccentric Moment, Low Cross-talks and High Durability *used to be patented.

General-purpose Vibration Test Systems G-0 Series

- Electric & Electronic Apparatus

- Vehicles

- Railway Vehicles

- Aerospace

- Others

A Variety of Choices

The G-0 Series Vibration Test Systems have a variety of choices according to customer’s requirements with Force Output ranging from 1kN to 200kN and a choice of the Guide Systems from Mechanical Bearing, Air Bearing and Hydrostatic Bearing. Horizontal Tables with Linear-guide Bearing and Hydrostatic Bearing Guide Systems are also optionally available.

Usable for a Wide Range of General Purpose Vibration Tests

With the main features of high frequencies and high acceleration, The G-0 Series Vibration Test Systems are most suited to vibration tests for automobile and electric & electronic parts, also usable for a variety of vibration tests for general purposes by adding necessary accessories such as vertical tables and horizontal tables.

Standard Specifications

- Cooling Method: Air-cooled / Water-cooled

- Guide System: Mechanical Bearing /Air Bearing /Hydrostatic Bearing

Options

- For Combined Environmental Tests

Catalog

Vibration Test Systems for Transportation Tests G-9 Series

- Seismic

- Transportation

- Electric & Electronic Apparatus

- Vehicles

- Railway Vehicles

- Aerospace

- Others

Suitable for Vibration Tests for Large products

The main features of large, robust Bare Tables and high Eccentric Moment make the G-9 Series Vibration Test Systems suitable mainly for transportation vibration tests for large heavy specimens such as packaged cargos and large automobile parts. With the Aux. Vertical Table and Horizontal table being added, the employment of the optional Geared-Motor for rotating the Vibration Generator's body and the Aux. Vertical Table UP-DOWN device with 4 cylinders makes a changeover of vibration directions more safe and easy.

Usable Up to 2kHz (Option)

Optionally available is 2kHz instead of standard 500 to 1,000Hz, making G-9 VTSs also usable for tests for vehicle parts and electric & electronic parts.

Standard Specifications

- Cooling Method: Air-cooled

- Guide System: Mechanical Bearing /Air Bearing/Hydrostattic Bearing

Options

- For Combined Environmental Tests

Catalog

Shock & Vibration Test Systems G-5 Series

- Seismic

- Electric & Electronic Apparatus

- Vehicles

- Others

Up To 4,900m/s2 (500G)

Shock Tests Possible

The unique structure of the Air Bearing Guide System & light Movable Mass permits for relatively high acceleration & large displacement thus making a wide range of shock tests with low to high acceleration & short to long duration possible, featured by high fidelity of controlled shock waveforms. Also G-5 Series Shock & Vibration test Systems can be used for a wide range of vibration tests including JEDEC Standards Random Test Service A*1and NEBS(Bellcore)GR-63-CORE Earthquake Tests*2 *1 About 140mmp-p displacement needed and some G-5 Series Systems can't be used *2 About 260mmp-p displacement needed and G-5NS Type only can be used.

Bump Tests Easily Achieved

Easy setting of the number of times of shock waveforms and interval time makes Bump Tests easily achieved, thus beating conventional Shock Test Machines in a way.

Up to 260mmp-p Displacement Available

The other feature of G-5 Series, a large displacement up to 260mmp-p, also allows for seismic simulation tests such as NEBS (Bellcore) GR-63-CORE Earthquake Tests.

Standard Specifications

- Cooling Method: Air-cooled

- Guide System: Air Bearing

Options

- For Combined Environmental Tests

Catalog

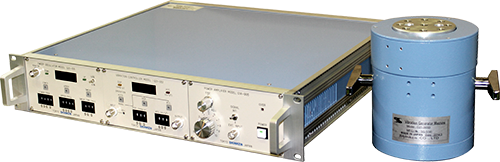

Miniature Vibration Test Systems G-2 Series

- Electric & Electronic Apparatus

- Vehicles

- Others : Calibration & Education

Usable in Small Space

Featured by compact and handy, the G-2 Series Vibration Test Systems (VTSs) can be put and used anywhere; even on a school desk (but smaller than the G-2005D) with no noisy cooling blower needed. (except the G-2050).

Small But For A Variety of Applications

The G-2 Series Vibration Test Systems, small but consisting of Sweep Oscillator, Sine Controller, Power Amplifier and Vibration Generator, can be used for a variety of applications; calibration of sensors, standard vibration tests for small parts, school teaching and modal analysis.

Expandable to…

Instead of the standard Power Amplifier with the Sine Controller, the combination of the Power Amplifier and the D-59 Series Controller is also available. Also available are Aux. Vertical Tables and Horizontal Tables.

Standard Specifications

- Cooling Method: Natural-cooled / Air-cooled

- Guide System: Mechanical Bearing

- Power Amplifier with Sine Controller

Options

- Air-cooled

- Mechanical Bearing

- Standard simple sine controller

Catalog

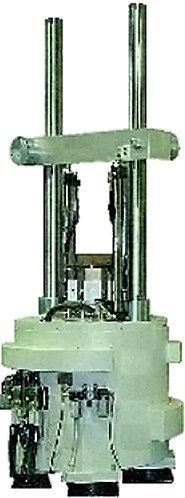

Shock Absorber

Test System

G-9210S

- Vehicles

- Others

Vibration Test Systems

with Gatepost Preloaded Mechanism

This is the Vibration Test System with the Gatepost Preloaded Mechanism for vibration tests with preload onto suspension system automobile parts such as shock absorbers with water-cooled systems also available for squeak & rattle tests.

Usage

- Vibration Characteristics Tests

- Vibration Fatigue Tests

- Vibration Endurance Tests

- Vibration Response Measurement

- Squeak & Rattle Tests